1. Cellulose Nanofibers (CNFs)

Cellulose is a limitless resource on earth, and cellulose nanofibers (CNF) has been widely researched from a new angle in recent decades. Due to a high water content of 98% and superior mechanical properties, CNFs have been applied as substrates of transparent films, porous packaging, tissue engineering scaffolds, hydrogels and aerogels, and battery electrodes. In recent years, CNFs has been used as an additive to ink for the enhancement of low viscosity in the ink and the directional deformation of structures, and as an embedding material for direct 3D printing.

CNFs can be produced in various ways such as homogenizing, microfluidizing, grinding and chemical treatments. Among such fibrillation methods, mechanical fibrillation using a grinder has been widely used due to its distinct advantages compared with chemical treatments. Highly viscous CNF dispersions with low concentrations of cellulose content can be easily produced using a mechanical grinder.

2. Matrix-Assisted Printing Systems

(Hydrogel matrix)

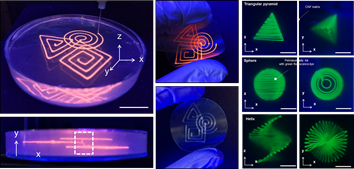

The current major problems in 3D printing are focused on inks and printing systems. However, in addition to ink, the matrix is one of the most critical components in 3D printing of soft matter. Nevertheless, matrix research is rarely reported due to the lack of selectable materials. The matrix plays an important role in maintaining printed structures in a free-standing form in the bulk space. Extrusion 3D printing using a matrix and ink was most effective for printing free-standing structures and a smart choice for the rapid prototyping of microfluidic systems due to the ease of processing and freedom of design. The free-standing 3D structures could be fabricated by extruding inks in the liquid matrix including PDMS prepolymers, self-healing hydrogels and granular gel media. We adopted a green material, cellulose nanofiber (CNF) hydrogel, as a potential novel matrix, and the critical factors are investigated for the 3D printing of free standing structures using this material.

(Solid matrix)

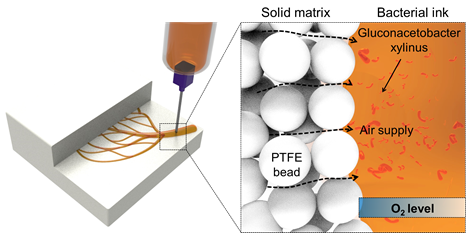

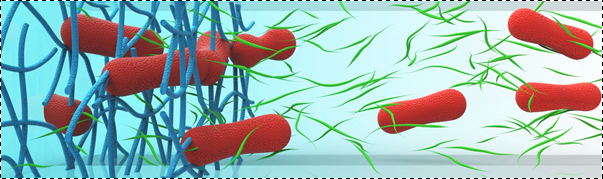

SMAP begins with the combined materials system of a viscoelastic hydrogel ink and a hydrophobic fluidic solid matrix. SMAP uses a cellulose nanofiber (CNF)-based viscoelastic ink containing active bacteria printable in a hydrophobic solid particle matrix. Support for extruded hydrogel structures is achieved by printing the ink in fluidic matrices such as a viscose liquid or non-adhesive solid particles. The fluidity of the selected solid particles enables 3D printing of hydrogel ink by rapidly filling the space created by needle movement. The hydrophobic solid matrix provides dimensional stability for the viscoelastic 3D structures as well as a gap space between the particles through which oxygen required for the biosynthesis of cellulose can be delivered. To fabricate free-form BC structures, the printed feature is exposed to air three dimensionally while retaining the 3D structure.

3. Bacterial Cellulose Hydrogels

Bacterial cellulose (BC) constituted of β-D-glucose units linked by 1-4 glycosidic bonds provides an ultrafine nanosized 3D network fibrous structure that could serve as a potential reinforcing matrix of composites. Its fibrils have diameters of several tens of nanometers with high crystallinity and it is also highly hydrophilic. In addition, the mechanical properties of BC are much better than those of conventional natural fibers. BC-based composites incorporated with inorganic nanoparticles and biopolymers are fabricated by employing suitable synthesis strategies, and their potential applications are investigated.

BC electromagnetic shielding nanocomposites

In situ polymerization of AuNPs-BC nanocomposite

Alginate/TOBC hydrogel composites

Thermosensitive hydrogel for cell encapsulation

4. Pickering emulsions

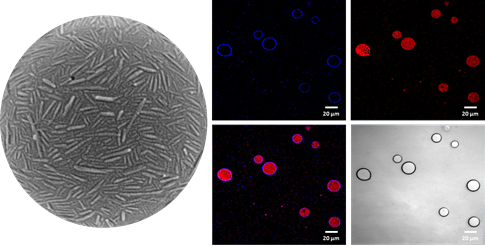

Cellulose nanocrystals (CNCs) have a high aspect ratio of crystalline fibrils as well as amphiphilicity. CNCs are attractive as stabilizers compared with other types of cellulose particles such as sphere and nanofibers due to the better control in morphology and reproducibility of emulsion formation.

Pickering emulsions (PEs) are one method for encapsulating a phase separating liquid phase with surface active particle. PE stabilizes biphases with different surface energies using amphiphilic particles instead of a low molecular weight linear surfactant. Cellulose nanocrystals (CNCs) are appropriate particles for PEs because they have a high aspect ratio of crystalline fibrils, as well as amphiphilicity.

The stability and morphology of PEs are closely related with the properties of emulsifying particles. A high aspect ratio CNC provides high structural stability to the emulsion and colloidal dispersion in the aqueous solution. Recently, emulsions stabilized with cellulose-based particles were demonstrated using microfibrillar cellulose, nanofibrillar cellulose and CNCs. Such a cellulose-based stabilizer for PEs is advantageous over synthetic or inorganic nanoparticles due to biocompatibility, degradability and cost issues.